So it happened to me. Recently I received some alert that my colocated servers were down at a local datacenter. There had been a power event where the UPS units there had failed causing a reboot of everything in this specific DC. While driving the the DC at 1am to figure out what was going on, I received alerts that some of my servers had came back up, while one had not. Upon arriving there were already a ton of people there dealing with their own equipment. Looking at my specific servers I could see there was a bad DIMM error on the front display, classically flashing orange. "All I need to do is press F1 To Continue" I thought, but unfortunately all of the crash carts were in use by other people there. Anyone who has Dell servers has seen this message during boot at some point if there has ever been any issues with their server. It is a classic error message which I wish Dell had always by default just made the server boot if possible. Because of the queue of people waiting for crash carts, I had to wait until one finally became available to press 'F1' to get my server alive. This could have easily been avoided if I had set this specific server to boot up regardless of error in the bios, but it was too late for this now.

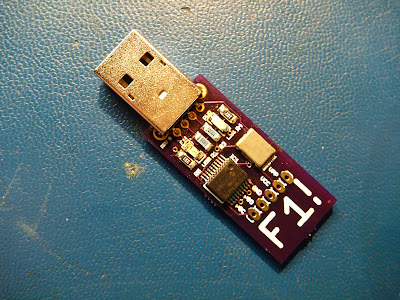

The solution? Well, make sure your servers are set to boot regardless of error in the bios. But a backup solution is my "F1 USB Stick":

What does it do? It is a UDB HID Keyboard that presses F1 repeatedly! That's all!

Simply plug it into a server and it presses F1 for you. No keyboard needed! Your server will be back up in no time.

F1!

I had fun with this one, looking at the kernel messages upon plugging in and you will see this:

usb 3-2: new full speed USB device using uhci_hcd and address 3

usb 3-2: configuration #1 chosen from 1 choice

input: Brad Boegler Press F1! as /class/input/input3

input,hidraw0: USB HID v1.11 Keyboard [Brad Boegler Press F1!] on usb-0000:00:1d.1-2

It is based on a Microchip PIC18F14K50 USB enabled microcontroller, a 12Mhz crystal, and the necessary passive components for operation and USB communication. I added a few LEDs in there just to be able to see what was going on. I wrote the code in Microchips C18 which utilizing Microchips USB libraries made this as simple as can be.

I will be keeping one of these in my laptop bag at all times... just in case. ;)