Since building my own GPS disciplined local time server I have wanted a large display of some sort to display my super accurate clock. The primary purpose of doing this was really just because it would be rally really cool looking. I also have a personal issue with any clock that does not set itself from the WWVB or support NTP, in 2015 we shouldn't have to manually set clocks anymore. A secondary use for doing this would be for ham radio purposes. A nice large clock that is always accurate so I can easily and quickly log contacts in UTC would be very useful. Ultimately I ended up with a very nice solution and here is the result:

|

| ESE ES-166 timecode display used for GPS clock |

Searching for someone who makes such a clock was frustrating. It seems either you can have a large format clock for cheap that does not support NTP, or you can have one that does support NTP but costs hundreds of dollars. Designing and building my own was the next option that I had considered for awhile. A simple PIC based device that drives some large 7 segment led displays would be trivial to build, but I couldn't get into the project. It just didn't excite me, It's one of those things that would be so simple and mundane that I just couldn't drive myself to do it. It would be like a software engineer being assigned the task of writing a word processor. It's already been done so many times and is such an unfulfilling project you can just never get excited about it.

So on to Plan C. Let's see what's already available and either modify or make it work for my intended use. Basically I would be looking for a large LED, backlit LCD, or big VFD display of some sort that would be able to easily display time. Input can be via various means, ethernet or serial would be first choices, some other parallel type interfaces would be not ideal although I could still make it work if needed. Luckily having some experience is professional video editing when I was in college, I looked towards something I felt might me the perfect solution: Timecode displays.

Upon scrounging around I found a perfect device on eBay, an ESE-166 remote timecode display. These can be found for less than $50 at times are are beautiful pieces of gear. It is a big 2U rack mount enclosure with a nice large format LED display on the front panel. This display is designed for displaying accurate time code for video editing systems. The particular display I purchased had hour, minute, and second digits which would be perfect. Many time code displays also include a 4th digit section for frames which this one did not as I did not need it for my purpose. The inputs on these devices are typically a single 75ohm timecode serial input for SMPTE timecode. I was fine with this as designing some hardware to convert an rs232 serial stream to SMPTE timecode actually sounded pretty fun, but I ended up not needing to. This specific display also included an rs232 serial input that supports a few ASCII time formats. This would be a perfect solution, just have a script that takes my local time directly off of the time server itself and dump it out the serial port to this display. There would be some very minimal latency with this obviously, but regardless this solution would be perfect! The ASCII format I chose to use is as follows:

Format #0: (CR)(LF)I(^)(^)DDD(^)HH:MM:SS(^)DTZ=XX(CR)(LF)

As for getting the time data into the ESE, it has two runtime options set by some dip switches inside. The first is a free running clock that when the serial port receives a time string, it updates the internal clock to the time received. The second option does not free run, you simply continuously provide the time signals to update at the interval you specify. In this option, you would need to provide the time signal at least once a second to keep the display real time. For now, I went with the first option. I have the ESE free running with a cron dumping data from my NTP server sending an rs232 time string via cron every five minutes. The noticeable time drift of this clock over a five minute period is not noticeable at all and this solution keeps the clock up to date on five minute intervals without having to constantly send it serial data.

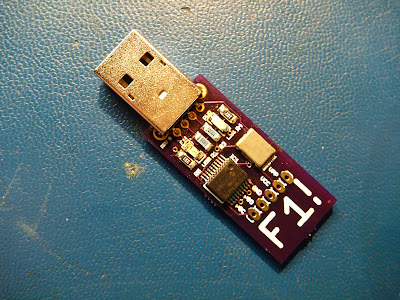

For those that are curious what is inside the ESE ES-166, it is pretty basic:

There is a whole lot of room in that chassis with not very much there. Just a mains transformer and simple analog rectified power supply with a handful of logic to decode the SMPTE / serial port data and drive the display. I'm planning on moving my Trimble GPS receiver inside of this case as there would be plenty of room for it. This would consolidate some of the hardware laying in the back of my server rack.

Additionally the manual for the ES-166 includes a schematic which is also nice to see. There was one part of the design that I really loved, the rs232 to TTL translation:

There is no serial driver there, MAX232 or equivalent. Just a simple level converter based on a 2n2222 with a diode and resistor. I love it! You see MAX232s in everything these days when they are often just not needed for serial RX conversion.

Further plans include racking this unit in my server rack and possibly getting a second unit so I can display both local time and UTC.