Recently and randomly I was notified from a friend about a local company liquidation auction for a local Unisys facility that was shutting down. Hoping to score some cool old vintage computer hardware I scoured the item listings to no avail. Nothing was really of interest, a lot of office furniture, shelving units, misc bins of random hardware bits. Ten years ago I would have been all over this auction, bidding on random carts of hardware to see what I can find but I just don't have time or the space for that anymore. After looking at a hundred or so pages of auction photos, one thing did catch my interest.

|

|

Hiding on an equipment cart was a Tektronix 2465B, sitting all by itself, the only piece of test gear in the entire auction out of hundreds of lots. I'm sure it was dead, the odds of it working and still being there were very unlikely. Having a 2445B, I have always wanted a 2465B, being the top of the line version at the time only second to the 2467 with its microchannel plate CRT. I ended up winning it for like 50 dollars including the cart which actually ended up being a really nice heavy duty equipment cart. Even if this scope was totally toast, it would still be a win for parts.

Once I actually picked up the scope and had a good look at it, it was in pretty good shape. The only physical damage was the vertical position knob for channel 2 being broken off, but this was visible in the auction picture. The rest of the scope was in really good condition, clean with no other physical damage.

|

| Tektronix 2465B |

Having restored my 2445B and knowing this will need a full re-cap, I ordered all the replacement caps for the power supply and A5 PCB boards. The power supply for the entire 24NN series was basically identical with a few minor revisions. One thing I did notice though was some of the capacitor values were different in this 2465B compared to the capacitor list I had for my 2445B. Instead of placing the order based on my old parts list, I created a new list based off the values in this scope. Some parts on my old DigiKey list were no longer available anyway.

Here is the updated DigiKey parts list:

| Quantity |

Part Number |

Manufacturer Part Number |

Description |

| 10 |

P10267-ND |

EEU-FC1E470 |

CAP ALUM 47UF 20% 25V RADIAL |

| 2 |

P13465-ND |

EEU-EB1H4R7S |

CAP ALUM 4.7UF 20% 50V RADIAL |

| 1 |

P5874-ND |

ECA-2WHG3R3 |

CAP ALUM 3.3UF 20% 450V RADIAL |

| 4 |

P10769-ND |

EEU-FC2A100 |

CAP ALUM 10UF 20% 100V RADIAL |

| 4 |

493-10252-1-ND |

UMP1H010MDD1TP |

CAP ALUM 1UF 20% 50V RADIAL |

| 1 |

399-7494-ND |

PME271Y510MR06 |

CAP FILM 10000PF 20% 1KVDC RAD |

| 2 |

399-5410-ND |

PME271Y422MR30 |

CAP FILM 2200PF 20% 1KVDC RADIAL |

| 1 |

EF2563-ND |

ECQ-E2563KF |

CAP FILM 0.056UF 10% 250VDC RAD |

| 2 |

399-7482-ND |

PME271M568MR30 |

CAP FILM 0.068UF 20% 275VAC RAD |

| 2 |

PCE3777CT-ND |

EEE-FK1A330R |

CAP ALUM 33UF 20% 10V SMD |

| 2 |

PCE3833CT-ND |

EEE-FK1V100R |

CAP ALUM 10UF 20% 35V SMD |

| 2 |

493-1421-ND |

UVZ2E331MRD |

CAP ALUM 330UF 20% 250V RADIAL |

| 10 |

P10323-ND |

EEU-FC1H101 |

CAP ALUM 100UF 20% 50V RADIAL |

| 1 |

P5856-ND |

ECA-2CHG100 |

CAP ALUM 10UF 20% 160V RADIAL |

| 4 |

P11236-ND |

EEU-FC1V271 |

CAP ALUM 270UF 20% 35V RADIAL |

| 2 |

P10345-ND |

EEU-FC1J181S |

CAP ALUM 180UF 20% 63V RADIAL |

Note that I ordered a few extra values of some of the caps to meet price breaks. Total cost came to $30.02 without shipping.

Just like on my 2445B, I always use high quality Panasonic 105 C caps and original replacement RIFA film capacitors. The couple non-polarized caps are 105 C Nichicons along with the two large filter caps. None of the resistors in this power supply were damaged like on my 2445B, so I left them alone on this one.

|

| 2465B power supply with new capacitors |

For my first power on test, the scope did power up, went through the first self-test cycling the panel LEDs, fan was running, but nothing on the CRT. Intensity controls had no effect. Even the graticule illumination was dead. Timebase, channel, and trigger controls responded to changes so the digital portions were at least working. Checking voltages, some were off and had ripple so I powered down and would wait for the capacitors to arrive.

Once all capacitors were replaced, powering up had the same result as before. Checking voltages they were all in spec now and the ripple I had was gone, but still no display. Time to reference the service manual.

One note on the 2465B service manual, I found three different versions all of which having some slightly different information. None of the info contradicted itself, just some manuals had more information than others. Once of the manuals looked to be for the older version of the 2465B where the A5 pcb was not using surface mount components, this was for early serial numbers . The other two looked to be newer. I ended up referencing all three throughout the repair process.

Following the troubleshooting flowcharts in the service manual, I ended up adjusting the grid bias adjustment which when increasing did give me a working display. Traces appeared along with on-screen graphics, but they were out of focus and had horizontal artifacts across the display. Intensity controls had no effect leading me to believe it was something with the Z axis processing based on the service manual flowcharts. The primary culprit would be the U950 hybrid which handles most of the Z axis functionality.

|

| 2565B with grid bias increased |

Since I did have a somewhat readable display, at this point I was able to run the self-test routine outlined in the service manual to verify the rest of the functionality. In doing this, the scope passed with no issues, so good news there. I could also check power-on hours and cycles, 15703 and 2440 respectably. About 5k more hours than my 2445B but still not a high amount compared to some 24NN's I have seen that are well over 30K hours.

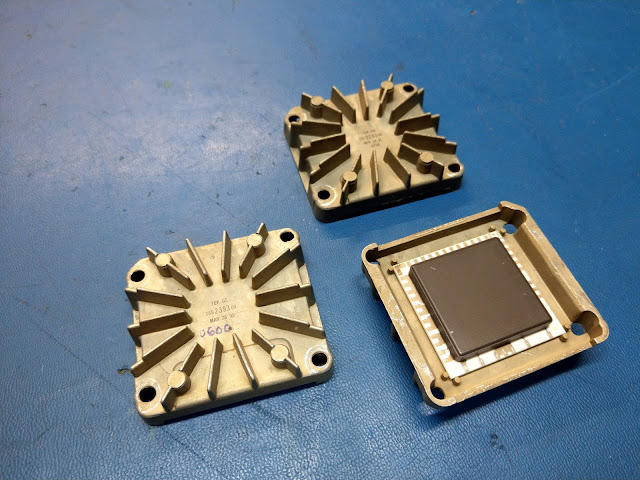

At this step, having a working donor scope makes troubleshooting significantly easier. All of the hybrid ic's on the main board are identical, with exception to U600 which has a different part number. 165-2393-00 on the 2445B and 155-0237-00 on the 2465B. Reading into this, they are compatible with the exception being that the 2445B version does not have 400MHz bandwidth. So I can use it for testing if necessary, it will just limit bandwidth on the 2465B to something under 400MHz. You would not want to use this long term in the 2465B.

Pulling parts from a working donor scope is always a little scary, I could end up with two non-working scopes in the process but parts are now plentiful on eBay for reasonable money.

|

| 2445B donating hybrids to the 2465B |

Swapping U950 from my 2445B to the 2465B did fix the display issue. After turning the grid bias back down, the intensity and readout intensity controls now properly function. The display has a nice clear readout and clean trace. Looking on eBay, a working tested replacement U950 is about $50 - $60 which has been ordered.

Checking the rest of the scopes functionality I did notice another problem. As I adjust the horizontal timebase, the trace will disappear after increasing it beyond 2ms. Turn it back down and the trace will reappear. This behavior repeats for all 4 channels and is Y axis independent. Applying a signal has no change on behavior. Either the built in square wave calibrator or an external signal from a signal generator, the scope will lose trigger right around 2ms then have no trace at all beyond 1ms. Changing any setting, 20mhz bw, delayed timebase, other triggering options, etc made no difference. So something is up with the horizontal timebase and / or triggering on this scope.

One first attempt was to swap out the remaining hybrid ic's from my 2445B to the 2465B to at least eliminate another one of them being a possible issue. This ended up making no difference, so the next step will be to go back to the service manual. Their is a lengthy flowchart to debug horizontal trace issues, following this will be my next step. I'll leave this for a part II of the repair.